When you shop on international marketplaces, products can arrive different than expected even when the listing looks clear.

These differences usually come from listing gaps, seller practices, and long delivery chains.

This article explains why it happens and how you can reduce the risk before and after you buy.

Listing vs. Reality

Listing vs. Reality highlights where buyers usually get misled on product pages. These are the main problem areas you need to check.

- Condition — “New” can still mean opened, tested, or repackaged.

- Variants — Dropdown options can change model, size, or version.

- Photos — Stock images do not show the actual shipped item.

- Inclusions — Accessories and manuals may be missing or replaced.

- Specs — Titles and detail sections can conflict.

Seller Practices That Affect Outcomes

Seller practices directly affect what you receive, even when the listing looks correct.

These behaviors are common on international marketplaces and explain many quality surprises.

- Mixed inventory — New, returned, and refurbished items stored together.

- Reselling — Sellers source products from wholesalers, not from the original brands.

- Dropshipping — Seller never handles the product before shipping.

- Weak inspection — Items ship without individual quality checks.

- Fulfillment outsourcing — Third parties pack and ship without context.

- Condition relabeling — Items listed as new after light use or testing.

- Batch fulfillment — Orders packed in bulk without item-by-item checks.

- Accessory substitution — Generic or incompatible parts included.

- Inventory aging — Old stock shipped without reinspection.

- Multiple supplier sourcing — Same listing fulfilled by different suppliers.

Platform Fulfillment Models

Platform fulfillment models control how items are stored, packed, and shipped.

These systems can change product condition even when the seller is reliable.

- Platform-fulfilled — Items ship from shared warehouses, not the seller.

- Seller-fulfilled — Sellers pack and ship items themselves.

- Shared stock — Identical listings pull from mixed inventory.

- Return restocking — Customer returns can be reentered into active stock.

- Automated routing — Orders ship from the nearest warehouse, not the best source.

- Inventory pooling rules — Items from multiple sellers mixed by SKU.

- Condition blending — New and returned units stored in the same bins.

- Auto reassignment — Orders reassigned to another seller mid-process.

- Cross-border fulfillment — Stock moved between countries before shipping.

- Priority routing — Speed is favored over condition or packaging quality.

Packaging and Handling Risks

Packaging and handling risks increase as products move through warehouses and long delivery routes.

These issues often explain damage, missing items, or signs of prior use.

- Repacking — Original boxes replaced with plain or damaged packaging.

- Missing inserts — Manuals, cables, or small parts left out.

- Weak protection — Minimal padding for long-distance shipping.

- Transit damage — Dents, crushed corners, or torn seals.

- Prior opening — Broken seals or retaped boxes.

- Label removal — Original barcodes, seals, or stickers removed during handling.

- Improper sealing — Tape applied unevenly or layered over old tape lines.

- Accessory mixing — Parts swapped with similar but incorrect or incompatible items.

- Inner damage — Product scuffed or scratched, even if the outer box looks fine.

- Loose packing — Item shifts freely inside the box during long transit.

International Shipping Factors

Here are additional factors to consider for international shipping. These also affect condition, packaging, and completeness.

- Security checks — Packages opened for screening and resealed without original packing.

- Weather exposure — Rain, humidity, or extreme temperatures during transit.

- Manual sorting — Human handling increases the risk of drops and crushes.

- Route changes — Rerouting causes extra stops and handling.

- Last-mile handoff — Final delivery partner may rehandle or repackage items.

- Customs backlog — Packages sit in holding areas for extended periods.

- Cargo compression — Heavy freight stacked on lighter parcels.

- Container shifts — Movement during sea or air transport causes an impact.

- Partial unloading — Boxes moved multiple times during sorting scans.

- Local carrier standards — Handling quality varies by country and region.

Regional Version Differences

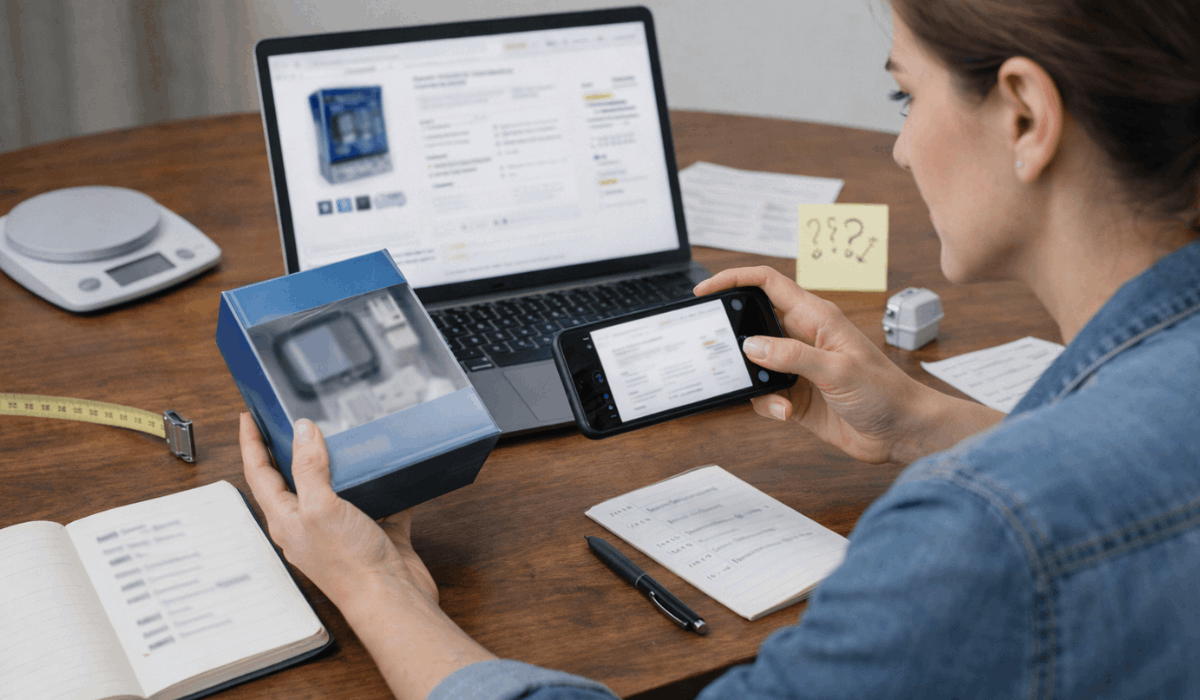

Regional version differences occur when the product shipped is made for a different market than expected.

These differences are common in cross-border listings that reuse the same page worldwide.

- Specifications — Hardware features vary between regional releases.

- Power and sizing — Voltage, plug type, and dimensions differ by country.

- Firmware and software — Features enabled or disabled based on region.

- Accessories — Cables, adapters, or chargers vary by market.

- Packaging and manuals — Box design and instruction language change.

- Compliance and certification — Safety and regulatory marks differ.

- Warranty coverage — Support is limited to the original sales region.

Translation and Listing Automation Errors

Here is the expanded version, with a few more words per line, keeping it clear and direct.

- Unit conversion errors — Sizes, weights, or capacities converted incorrectly between regions.

- Feature name mismatches — Functions renamed or misinterpreted during auto-translation.

- Option-label errors — Variant names do not clearly match the actual item shipped.

- Auto-filled attributes — Platform systems insert incorrect default specs.

- Removed disclaimers — Condition limits or usage notes dropped during translation.

Buyer Timing and Assumptions

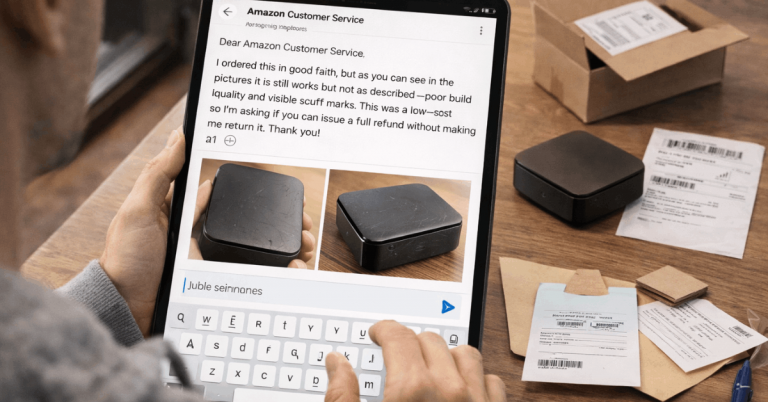

Buyer timing and assumptions can turn small issues into major problems. Delays and unchecked expectations reduce your ability to fix mistakes.

- Late inspection — Problems found after the return windows close.

- Assumed condition — Trusting “new” without verifying details.

- Skipped checks — Ignoring variants, inclusions, or specs.

- Missed deadlines — Buyer protection timelines expire.

- Informal contact — Messaging sellers outside the platform.

- Rushed checkout — Buying quickly without reviewing full listing details.

- Price bias — Assuming a higher price guarantees better condition.

- Brand trust — Expecting quality based only on brand name.

- Delayed documentation — Failing to take photos on delivery day.

- Partial inspection — Checking the item but not accessories or packaging.

How to Reduce the Risk

You can reduce the risk of receiving a product that falls short of expectations by using a controlled buying process.

These steps help you prevent issues and protect your options if something goes wrong.

- Verify listings — Match title, specs, variants, and inclusions.

- Check sellers — Review recent feedback and fulfillment method.

- Choose protected shipping — Use tracked and insured options.

- Document delivery — Photograph boxes and seals before opening.

- Act fast — Report issues within platform deadlines.

- Confirm region compatibility — Check voltage, sizing, and market version.

- Read recent photo reviews — Look for real condition and packaging proof.

- Save listing evidence — Screenshot the page before checkout.

- Keep platform communication — Message sellers only inside the system.

- Check return rules early — Know limits before you buy.

The Bottomline

Products arrive differently than expected because listings, sellers, and delivery systems are not perfectly aligned.

You reduce problems by checking details, choosing reliable sellers, and documenting deliveries.

Use this guide before you buy, and act quickly if something looks wrong.