Buying cross-border means you often decide without touching the item, so product durability depends on the materials you can verify in advance.

You rely on material claims, listing details, and other buyers’ photos to confirm what will hold up over time.

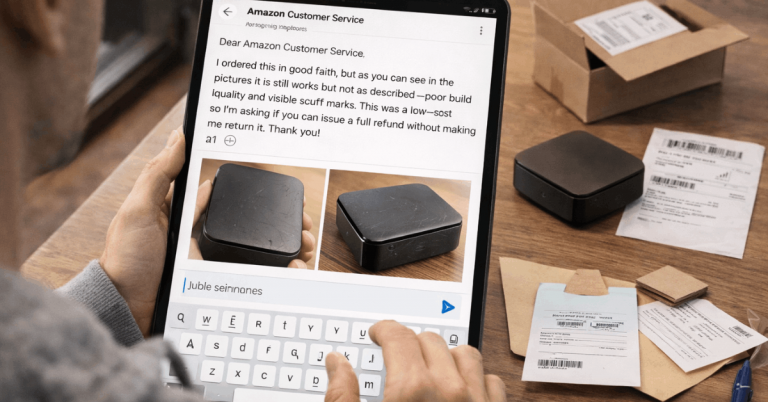

When those signals match, you cut down on returns and disputes, and when they do not, delivery time and seller support become part of the durability problem.

Why Materials Matter More Than Marketing

Materials predict how a product handles stress, heat, moisture, and daily friction. Marketing terms rarely tell you what will fail first.

- Materials shape lifespan through cracking, bending, corrosion, and abrasion.

- Materials affect safety when weak parts snap, overheat, or shed coatings.

- Materials affect performance because fit and strength depend on thickness and density.

- Cross-border risk rises when listings are vague, and batches change over time.

Quick Material Check Before You Buy

You do not need lab testing to make better decisions. You need a repeatable routine that forces claims to match evidence.

- Read the spec area for material type and any grade or standard.

- Use weight, thickness, or size details as basic reality checks when available.

- Confirm with the buyer photos showing edges, seams, connectors, and underside surfaces.

- Save screenshots of the listing’s material claims before checkout for dispute proof.

Plastics and Durability Signals

Plastics range from stable, impact-resistant, and thin to brittle. Many listings only say “plastic,” so reviews and photos matter more.

Stronger plastics you want to see

Some plastics are commonly used for tougher shells and parts. You still need proof that the delivered item matches the listing.

- ABS and polycarbonate are common in cases, housings, and rigid covers.

- Nylon often performs well in parts that flex or are subject to abrasion.

- Thick corners and reinforced ribs in buyer photos beat “premium” wording.

Red flags in plastic products

Weak plastic often fails at corners, clips, and hinges. Repeated failure points across reviews are strong evidence of durability.

- Micro-example: a phone case cracks at the corners because the corners are thin.

- Reviews mention warping near heat or a strong chemical smell at unboxing.

- Buyer photos show thin walls, sharp mold lines, or uneven thickness at stress points.

Metals and What They Usually Mean

Metal can last, but grade and finish matter. “Alloy” can hide thin plating or weak processing.

Stainless steel vs “stainless” claims

“Stainless” is not a full spec. You need clearer details and proof of review, especially in humid environments.

- Prefer listings with consistent material details across variants, not just “stainless.”

- Check review photos for rust dots, discoloration, and pitting after short use.

- Dispute tip: screenshot the “stainless” claim and photograph early rust close-up.

Aluminum and coatings

Aluminum is light, but coatings control wear and corrosion. Weak finishes can chip at corners in shipping.

- Anodized finishes often resist wear better than thin paint layers.

- Painted aluminum chips more easily if the packaging allows movement inside the box.

- Micro-example: a coated metal item chips on arrival, then rust appears at the chip.

Fabrics, Stitching, and Wear Over Time

Fabric items often fail at seams, zippers, and strap anchors, not the main panel.

Fabric types and what to expect

Fiber type affects abrasion, stretch, and washing. Match the fiber to your use and climate.

- Nylon is often stronger for abrasion in bags and outer layers.

- Polyester varies widely and can pill when the weave is weak.

- Cotton can shrink or fade, so time-based reviews help you judge risk.

Practical checks for fabric listings

Construction quality is usually visible in buyer photos. If stress points look weak, returns become more likely.

- Micro-example: a backpack seam fails at the strap base due to low stitch density.

- Watch for loose threads, seam puckering, and zipper-end damage in the photos.

- Dispute tip: photograph broken zippers and torn seams before you use the item.

Leather, “Vegan Leather,” and Material Substitutes

Leather terms are often confusing on marketplaces. Your best signal is how the surface ages in real-use photos.

Real leather terms that matter

Some terms are more informative than others. You still need photos of the edges and the underside to confirm the claim.

- Clear terms like full-grain or top-grain are usually more informative than vague labels.

- Buyer’s photos of edges and the underside can reveal a heavy coating and a weak structure.

- Seller risk signal: repeated “not as described” material complaints across months.

PU leather and “vegan leather”

PU materials can look fine at arrival and fail weeks later. Heat, humidity, and friction speed up peeling and cracking.

- Micro-example: PU leather peels after a few weeks on a daily-use bag handle.

- Watch for peeling at folds, corners, and strap attachment points in review photos.

- Return tip: document the peeling close-up, plus wide shots showing the overall condition.

Wood, Engineered Wood, and Furniture Risk

Furniture is a high-risk cross-border item due to shipping damage and humidity. Core material and joints drive long-term stability.

Solid wood vs engineered wood

Core material affects screw holding, edge stability, and moisture response. Missing specs raise durability and dispute risk.

- Micro-example: MDF swells at the edges after delivery due to humidity, and the laminate then lifts.

- MDF and particleboard are more vulnerable at edges and joints when sealing is poor.

- Plywood can be more stable, but thickness and hardware still matter.

Build and packaging clues

Delivery survival often decides your outcome. Packaging proof is one of the best predictors for cross-border furniture.

- Prefer reviews showing foam inserts, edge guards, and tight internal bracing.

- Check buyer photos for chipped corners, cracked panels, and stripped screw holes.

- Dispute tip: photograph the unopened box, then the packing, then the damage before assembly.

Glass, Ceramics, and Fragile Materials in Delivery

Fragile items may last in use but break in transit, so packaging matters most.

- Micro-example: a glass item arrives broken due to minimal padding and loose space.

- Prefer listings and reviews that show double boxing and molded foam protection.

- Refund tip: document packaging, break points, and shipping label in the first photos.

Coatings, Finishes, and Hidden Weak Points

Coatings can hide weak materials, so judge finishes using wear photos and repeat complaints.

- Watch for peeling, bubbling, flaking, and discoloration after short use.

- Thin plating often fails first at edges and contact points, then corrosion follows.

- Delivery link: chipped coatings on arrival often indicate weak packaging and handling risks.

Fit, Compatibility, and Material Mismatch Issues

Durability depends on your environment and setup. Cross-border orders add region and rating mismatch risk.

- Climate exposure matters: UV, humidity, salt air, and temperature swings change wear speed.

- Load ratings matter for mounts, shelves, hooks, and stands, so missing load limits increases the risk.

- Electrical items need a region with plugs and voltage suitable for their use to avoid heat-related failures.

Review Proof Checklist for Material Claims

Reviews only help when they match your exact variant and show real evidence. Photos and time-based updates matter more than star ratings.

- Confirm the review matches your size, color, and version before you trust it.

- Prioritize photos of edges, seams, connectors, underside areas, and labels when present.

- Prefer reviews that mention weeks of use, not only unboxing impressions.

- Save screenshots of key claims and photos so you can quickly support a dispute.

Seller Reliability and Listing Honesty Signals

Reliable sellers give clear specs, consistent variants, and workable returns.

- Prefer sellers with consistent specs across variants and clear material details.

- Treat repeated “material changed” or “not as described” complaints as high-risk signals.

- Avoid off-platform pushes, as they weaken protections and complicate disputes.

Conclusion: Buy Based on Materials, Not Hype

You reduce returns by verifying materials and product durability using specs, buyer photos, and time-based reviews before you buy.

You also protect yourself by saving listing proof and documenting packaging and defects at delivery.

Use this material-check routine on your next cross-border order to avoid weak builds and buy smarter.